Design

Concept Development

From napkin sketch to production-ready geometry—we refine ideas into manufacturable solutions.

Material Selection

We help identify the ideal composite system (carbon, fiberglass, aramid, thermoplastics) based on your performance, cost, and durability needs.

CAD & 3D Modeling

Precision 3D modeling in SolidWorks and Fusion 360, optimized for composite layups and moldability.

Structural Analysis

Basic FEA to advanced laminate theory and load path optimization to ensure performance with minimal weight.

Design for Manufacturability (DFM)

Design rules that reduce cycle times, defects, and rework in production.

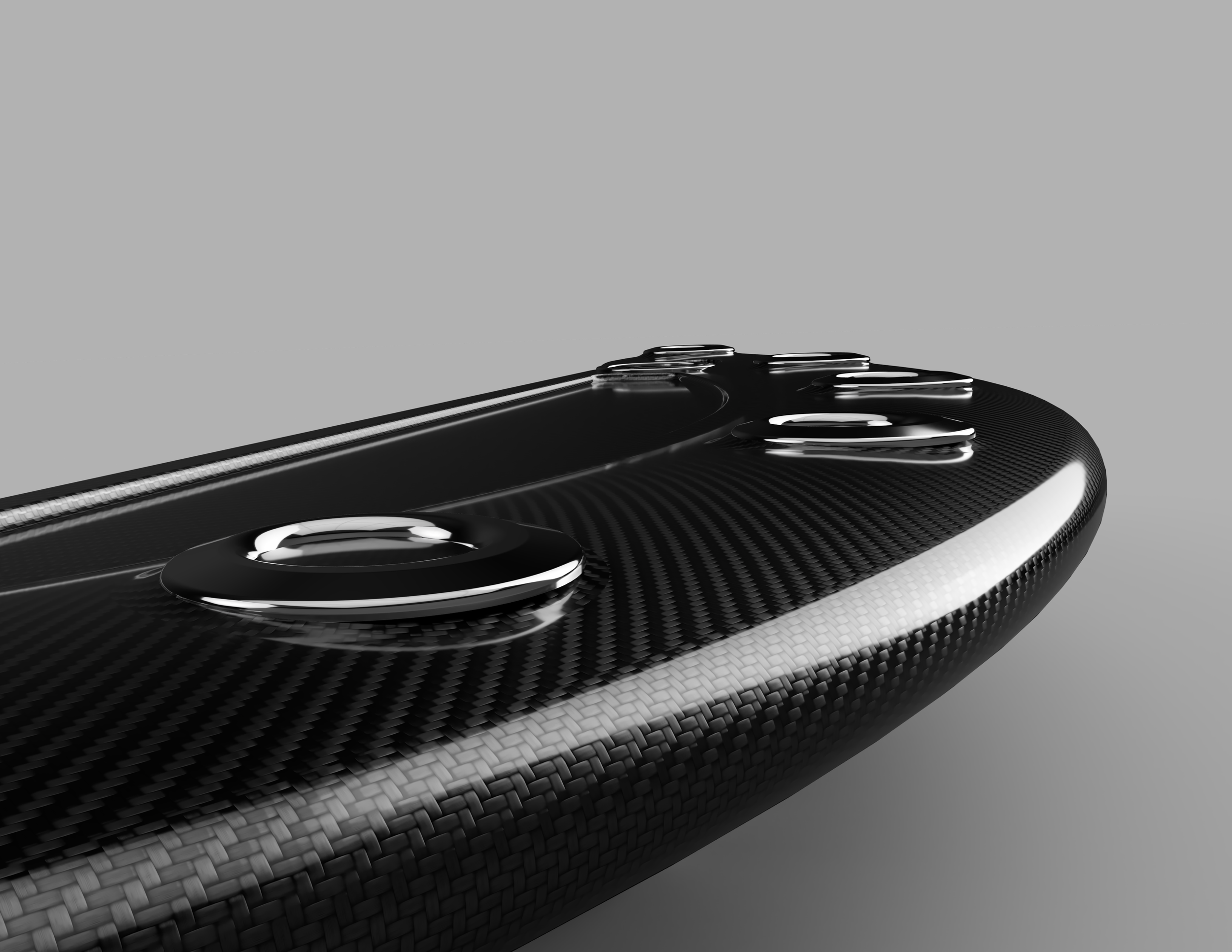

Visual & Surface Aesthetic Design

Designs that perform and look sharp—custom finishes, surface textures, and woven ply symmetry.

Manufacturing

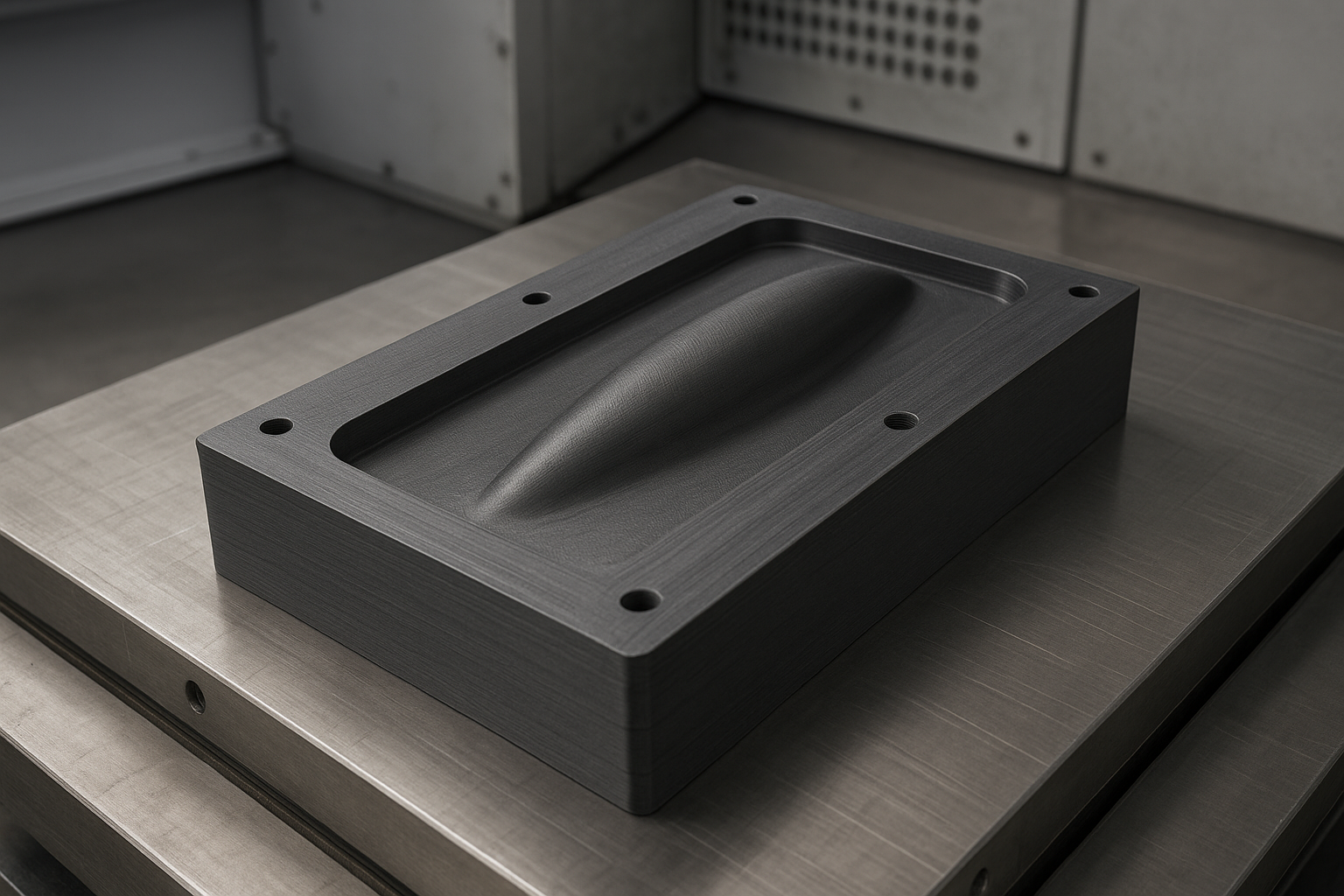

Mold Design & Fabrication

In-house tooling via CNC and high-temp 3D printing. Supports RTM, compression, vacuum bagging, etc.

Rapid Prototyping

Fast-turnaround parts using printed, machined, or open mold methods.

Composite Layup & Curing

Wet layup, prepreg, vacuum bagging, and custom cure cycles tailored per application.

CNC Trimming & Finishing

Multi-axis precision machining for tight tolerances and clean finishes.

Tolerance Engineering

Repeatable manufacturing to spec for aerospace, medical, and defense-grade parts.

Assembly & Integration

Bonding, insert molding, and multi-material part integration (metal-composite hybrids).